Research Activities

“If you are to do important work then you must work on the right problem at the right time and in the right way. Without any one of the three, you may do a good work but you will almost certainly miss real greatness…”

Richard Hamming

The research directions in the Multi-Scale Product & Process Systems Engineering Laboratory center on a fundamental understanding, theoretical development, and practical application of key issues in the areas of (i) Machine learning and optimization for decision-making under uncertainty, (ii) Autonomous optimization and control for MODERN manufacturing, and (iii) Multi-scale Process Design, Synthesis and Innovation toward Carbon Neutrality. Therefore, we strategically integrate different technologies across broad temporal and spatial scales, from the molecular/atomic level to the mesoscopic/ macroscopic levels.

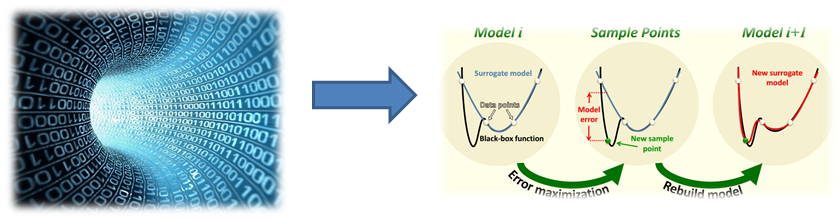

Machine Learning and Optimization for Decision-Making under Uncertainty

Within this direction, our research activities integrate the (dynamic) data reconciliation and (dynamic) data-driven modeling technologies based on machine learning to effectively describe (dynamic) chemical processes. We fundamentally develop the controlled-accuracy theories and on-line updating strategies for building data-driven models. We then address data-driven optimization under uncertainty methods such as adjustable robust optimization and distributionally robust optimization for making decisions. The relevant applications involve the enterprise-wide planning, scheduling, real-time optimization of chemical processes; process design and synthesis under uncertainty; and the product/material design and discovery.

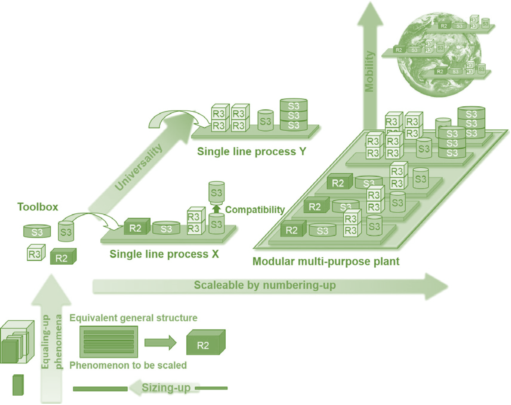

Autonomous Optimization and Control for MODERN Manufacturing

MODERN (Modular, Operable, DigitalizEd, and RecoNfigurable) manufacturing would be the next-generation technology for producing, purifying, characterizing, and scaling a wide range of medicines, fine chemicals, and advanced materials.

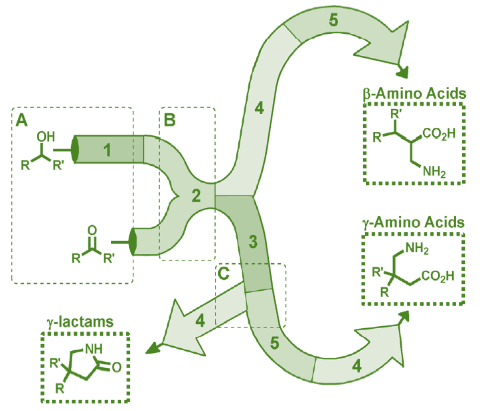

We focus on the following features: 1) Creating fundamentally new automated closed-loop systems that enable rapid design, discovery, and optimization of molecules with defined properties. 2) Developing autonomous platforms that discovery, configure, validate potential synthetic routes for targeted molecules considering the availability of feedstocks and operability of manufacturing processes. 3) Pursuing learning based autonomous optimization and control technologies for scaled-up modular and reconfigurable manufacturing processes.

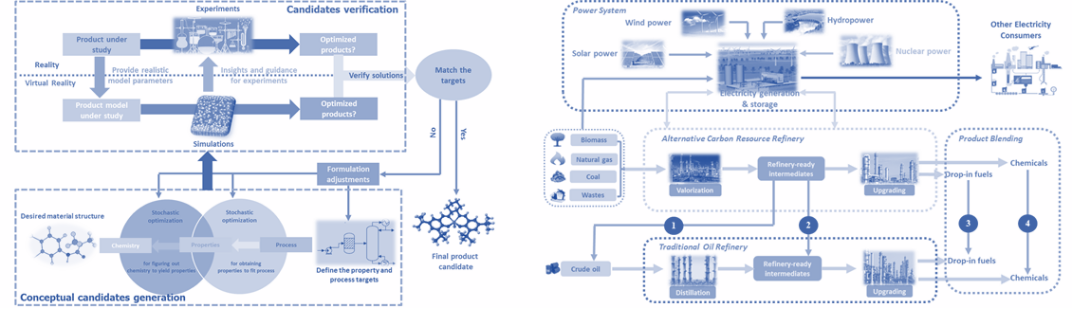

Multi-scale Process Design, Synthesis and Innovation toward Carbon Neutrality

Towards Carbon Neutrality, we propose a computation-experiment-system evaluation framework for reliable material discovery (Efficient adsorbents/membranes for CO2 capture, green solvents/catalysts for CO2 conversion and renewable energy utilization, solar cells for energy storage, to name a few). Promoted by the discovered functional materials, we also aim at the development and deployment of novel processes for producing renewable ammonia, aviation fuels, and recyclable polymers.